Semi-automatic capping machines

Easycap

Beverage

Beverage Cosmetic

Cosmetic Food

Food Chemical

Chemical Pharmaceutical

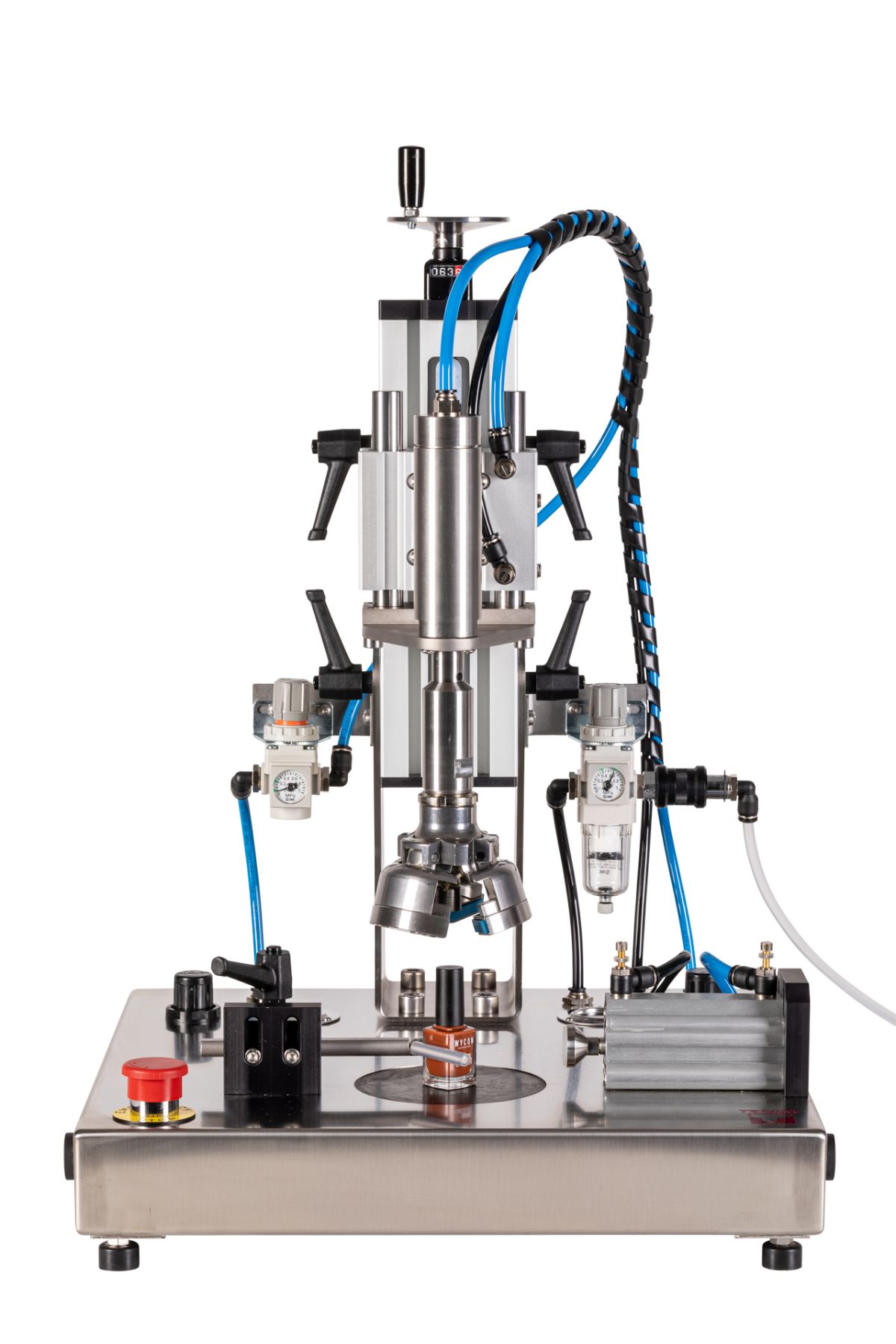

PharmaceuticalEASYCAP - Pneumatic Capper for Twist-Off Caps and Plastic Screw Caps

The EASYCAP pneumatic capper is a versatile and compact solution designed to ensure the secure and efficient closure of a wide range of containers with twist-off caps or plastic screw caps. Thanks to its fully pneumatic operation and benchtop design, EASYCAP offers high production flexibility, allowing for the processing of different cap formats and types. It is the ideal choice for small and medium-sized producers looking for a reliable solution for automated capping.

Technical specifications

Some technical data to know more about Easycap

Specifications

- About 600 p/h

- 472 x 450 x 675 h

- 30 Kgs

- 2 - 6 bars

- from 1.5 N/m to 7 N/m

- 450 l/min

- 240 l/min

- 40 mm

- 350 mm

- pneumatics

Configurations

- 38 mm

- 43 mm

- 48 mm

- 53 mm

- 58 mm

- 63 mm

- 66 mm

- 70 mm

- 77 mm

- 82 mm

- 100 mm

- 110 mm

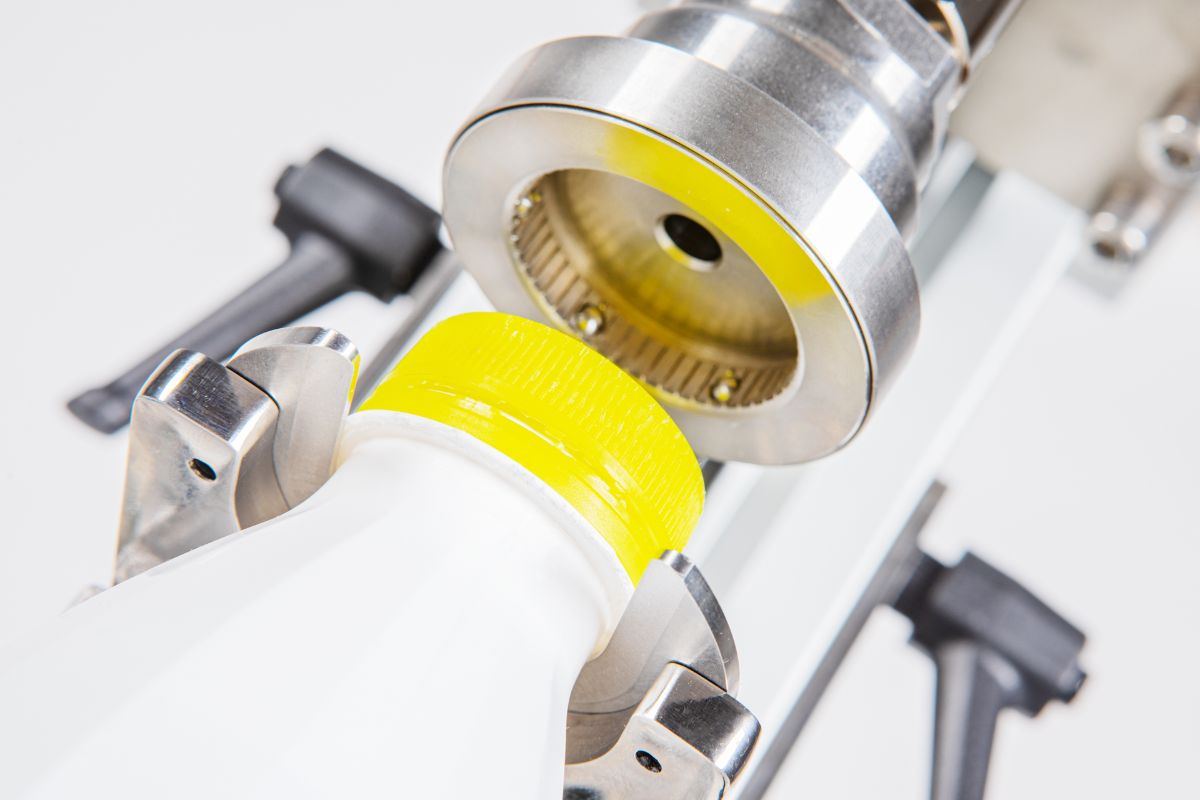

- ribbed mandrel for closing plastic screw caps with diameter up to 50 mm

- ribbed mandrel for closing plastic screw caps with diameter between 50 and 60 mm

- ribbed mandrel for closing plastic screw caps with diameter between 60 and 70 mm

- ribbed mandrel for closing plastic screw caps with diameter between 70 and 80 mm

- ribbed mandrel for closing plastic screw caps with diameter over 80 mm

Packaging

- low twist off with and without safety button

- twist off deep with and without safety button

- pre-threaded plastic caps

- pre-threaded screw-on aluminium caps

- smooth plastic caps

- flip top caps

- pump caps

- caps with applicator

- anti-choking plastic caps (baby caps, wavy caps, baby caps +, brick caps, tethered caps, caps with vaporizer)

- DIN61 caps with vent

- screw caps with HDPE gasket

- seal caps

Video Gallery

To see Easycap in action in various versions and for different applications, you can explore our video library.

FAQs

Do you still have any doubts? Here you will find all the answers you need.

Is the compressor included in the delivery? What type of compressor do you recommend for the operation of the Easycap capper?

The compressor is not included in the delivery. The minimum required compressor is at least 80/100 Lt of 2Hp tank of power and at least 300 Nl/min of air flow. Possibly silenced and absolutely non-lubricated compressor (possibly equipped with an air filter, if not a dryer).

No, the tappi sigillo capper operates completely pneumatically and is not available in the electric version. In case you need an electric machine, you can choose our Screwcap capper.

When I purchase the tappi sigillo capper for closing jars, can the mandrel adapt to different formats?

No, the tappi sigillo pneumatic capper must necessarily be adjusted for each format to be closed. This means that if there are several cap formats, it is necessary to purchase three closure mandrels (one mandrel for each format).

By regulating the pressure of the compressed air that feeds the motor, the higher the pressure, the greater the force applied.

The descent speed of the screwdriver must never be adjusted to maximum speed. It is used to optimize the performance of the capper: it is necessary to find the right compromise between the rotation movement and the descent speed of the spindle according to the type of container and the type of cap to be closed. For example, on some plastic screw caps the descent speed may be greater, while in the twist off it is necessary to work more slowly.

All available configurations

The machine can be configured on demand to meet all needs

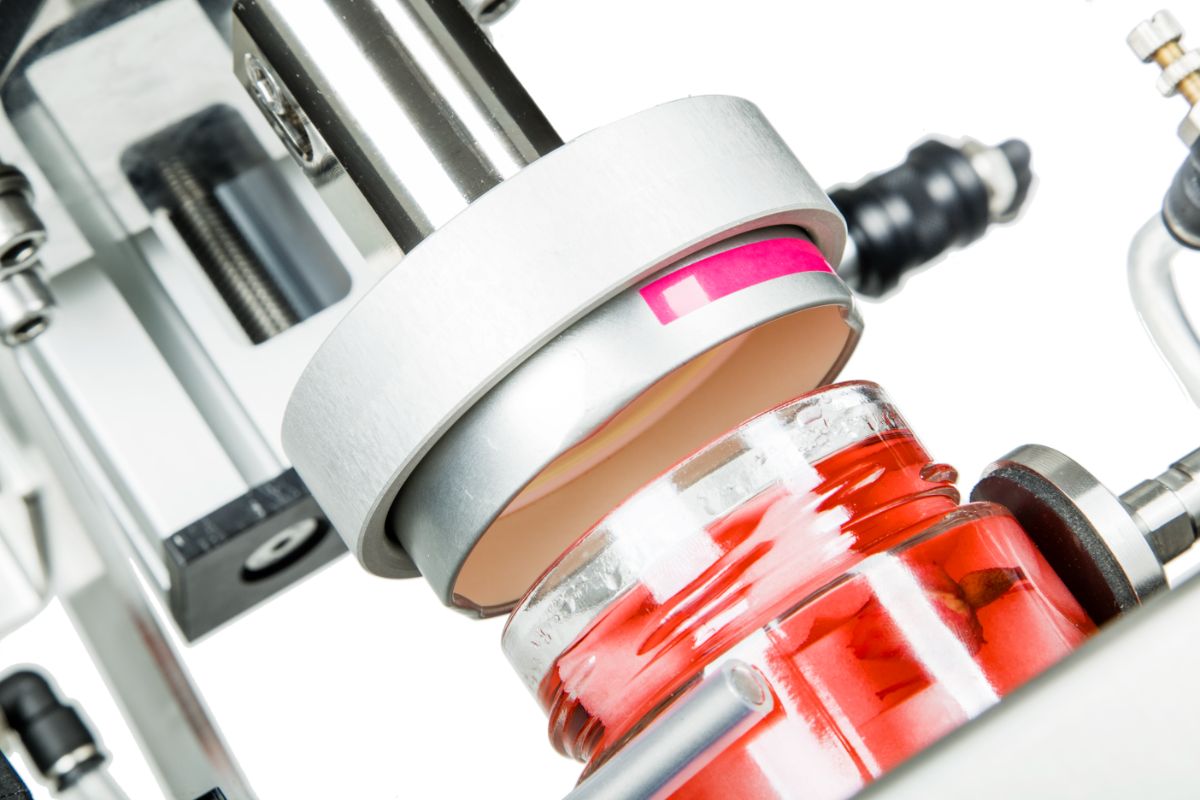

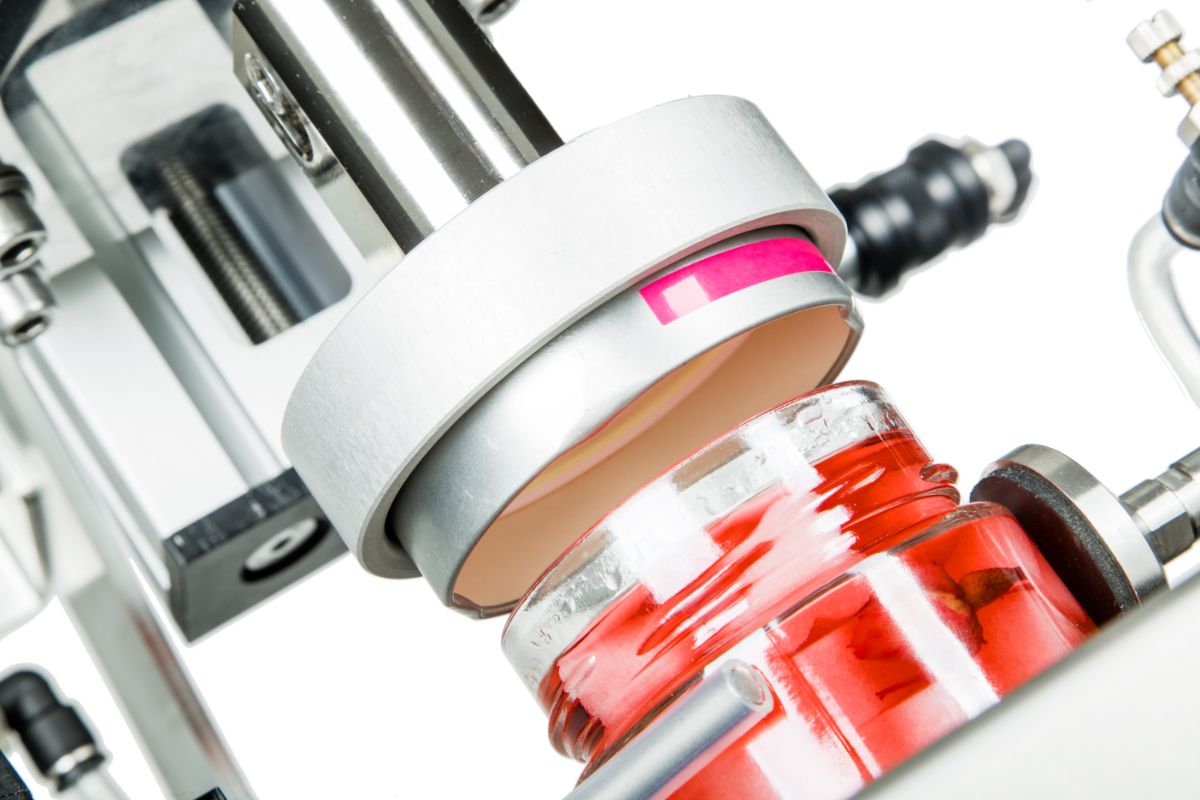

Pneumatic capsule version for twist off capsules

Fully pneumatic benchtop capper suitable for closing all twist off capsule formats with sizes from 38 mm up to 110 mm (standard twist off lid and high twist off lid) with or without safety button. Maximum height of the container …

Pneumatic capsule version for plastic screw capsules

Fully pneumatic benchtop capper suitable for closing all formats of plastic screw caps. Fully pneumatic operation: by pressing the two side buttons, the screwer descends and seals the capsules on the neck of the container in a few seconds. The …

Pneumatic capper version with 3-sector clamp

Fully pneumatic bench capper suitable for closing all plastic caps particularly used in cosmetics such as dispenser caps, flip tops and vaporizers. Fully pneumatic operation: by pressing the two side buttons, the screwer descends and seals the capsules on the …

Products that might interest you

Discover all the filling products similar to Easycap

Talk to a consultant

Need specific information about this machine? Enter your email address to be contacted by a specialized consultant